about our stripping Tools/ Dies

Welcome to a new era of efficiency and innovation in die cutting with Ashok Punch Arts. Our revolutionary approach to die cutting is exemplified by the unique design of our patented stripping claws in the upper tools, paired with specially engineered apertures in the lower tools. This groundbreaking design transforms the die cutting process by effectively handling waste scrap with unparalleled precision and speed.

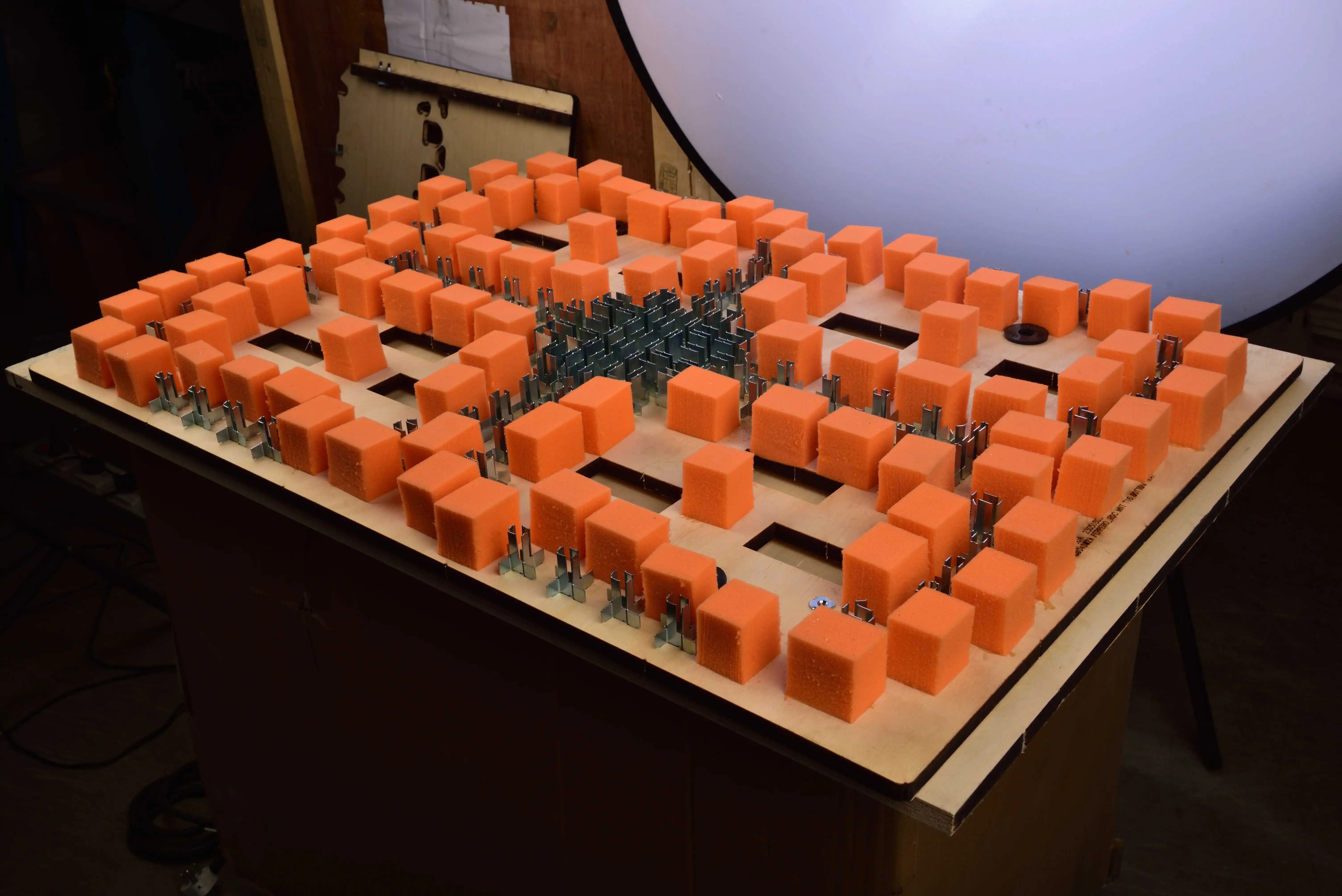

The patented stripping claws play a pivotal role in this advanced system. As they engage with the waste scrap, they pierce through it, seamlessly navigating the intricacies of your design.

The specially designed apertures in the lower tool provide a channel for the waste scrap to be forced through, releasing it effortlessly, resulting in a cleaner and more efficient die cutting process.

Critical vacuum holes strategically incorporated into the upper tool further enhance the overall productivity on the press. This strategic placement ensures improved stripping action from our patented stripping pins, without compromising press speeds or carton quality. The result is a seamless integration of cutting-edge technology, offering enhanced efficiency and precision in every die cutting operation.

One of the standout features of our innovative system is that, in most jobs, bottom pins are not required. This not only streamlines the die cutting process but also leads to significant time savings during make-ready. With no need to stop the press for adjustments, you can experience a remarkable reduction in downtime, allowing for a more efficient and cost-effective production cycle.